Untapped energy on every wall

Innovations by Skanska

Tomasz Cudowski, ‘Eurobuild CEE': How did you start working with Skanska?

Olga Malinkiewicz, CEO and CTO, Saule Technologies: Less than two years ago, when our laboratory was already up and running and we had carried out the first successful tests, we decided that we were ready to license the technology, and so we put it out to tender. Skanska was one of a number of companies that responded. Not only did it offer the best terms, but it also turned out that it had a similar approach to us: our product is ideal for use in office buildings and Skanska attaches great importance to the energy consumption of its projects and their environmental sustainability. Also, it does not hesitate when it comes to investing in innovative systems that are ahead of their time. Now we are also preparing to sell licences in other countries, such as in the Middle East, and from 2019 in Asia too.

So let's start with the basics: what are perovskite cells?

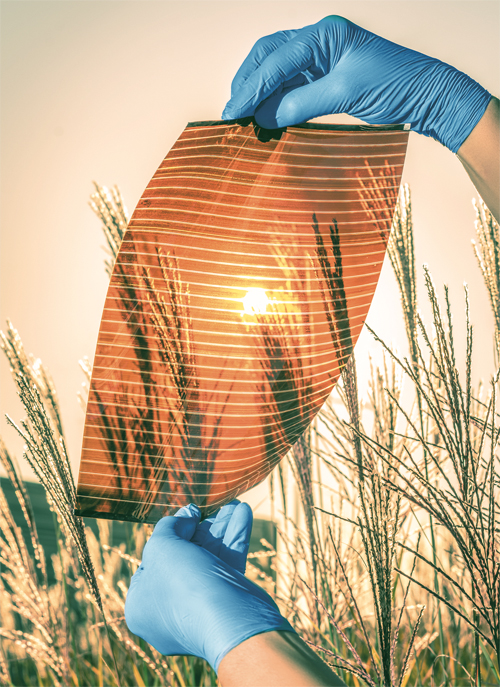

The perovskite material we use can be created under the right conditions using commonly available elements with the right admixtures. The structure this creates has amazing properties. So far photovoltaics have been associated with silicon cells, which are large, heavy panels – but now we have the technology to produce perovskites in the form of ink, which is simply printed onto a plastic film. Such a cell is perfect for absorbing light and converting the energy into electricity. The structure can be printed onto virtually any material, but we chose plastic film because it is cheap, light and flexible and can be formed into any shape. And you can put the cells made out of it onto any surface, including the façades of buildings.

Perovskites can be printed onto flexible plastic sheets, which means that solar cells can be created of any shape

Roofs are not enough anymore?

Exactly – the roofs of commercial buildings are usually cluttered up with various installations, or even greenery and outdoor furniture, if it has a terrace on it. Façades, on the other hand, are basically unused. But the owner would probably object to installing silicon cells on them, as these are heavy panels and would obscure the glass elevation – and this certainly wouldn’t look good. Solar farms require huge spaces and there are not many available in cities. Also silicon cells are not easy to shape – large silicon blocks have to be smelted and cut into plates with large surfaces; whereas perovskites, as I’ve already mentioned, can be printed onto any shape of film. The printing process is rather similar to that used by the inkjet printers people have in their own homes.

Does perovskite ink come in any colour?

There are a wide range of colours that perovskites could easily come in. Such as the darker colours: blacks and browns, as they absorb solar energy the best, but also reds and oranges, which are ideal for the construction sector because of their resemblance to classic brick or tile. Other colours are also possible – but with Skanska we will are only going to be testing green and blue cells. Theoretically, it is also possible to produce neutral-coloured or highly transparent cells, but these are still at an early stage of development.

The basic components of the perovskite material you use are generally well known, so the composition cannot be patented. What’s the secret behind how your cells function?

The material it’s made out of is not everything. The structure of the cell is more important as well as the admixtures used and the other cell layers – and this is the system we have patented. The basic composition of perovskite material has been known for a long time. It has already been tested as a cheap silicon replacement in diodes and transistors, but it was never tested for use in photovoltaic cells up until now. If twenty years ago someone had come up with this idea, perovskite cells would probably already be fully developed and widely available. However, the first perovskite ink was developed in laboratory conditions only as recently as 2009 and was applied on a larger scale just three years later. Perovskites can be creted in a laboratory in a relatively simple process. In contrast to silicon, you don’t need to extract and melt it or wait for weeks to synthesise it, as is the case with fullerenes. Metaphorically speaking: perovskites are like exclusive dishes prepared by a chef from basic ingredients – the secret lies in the recipe, the spices and the skills of the master chef. And we guard the full recipe for our cells with our lives – and only select employees having access to it.

What’s the most difficult part of introducing a completely new technology? The lack of any previous yardsticks to work by? Or the discouragement that follows from unsuccessful tests?

There have been plenty of unsuccessful tests, but the satisfaction derived from the successful ones and the excitement of discovering a whole new field of life and technology completely makes up for that. We are just setting up our first production line. Prior to this we spent several years in the laboratory. We didn’t have any studies or textbooks that we could use to tell us how to proceed. However, this technology will transform the electricity market – we are sure of it. For the first time in history we have a way of generating energy that can compete with fossil fuels in terms of costs per kWh. As well as the advantages for business, this technology is also very environmentally friendly: it uses ‘green’ solar energy and doesn’t generate any waste. It was only a few years ago that it seemed that silicon was unrivalled in this respect, but at an early stage perovskites already represent serious competition for silicon, so we can assume that they will eventually surpass it.

Developing new technology must take a lot of time and money. Have you got these?

As in any business, the financial side of the venture is very important. We not only have to support ourselves, we also need to do the development work. Fortunately, we are slowly starting to monetise our idea by licensing the technology. Skanska will use it in its construction works, but perovskites can be used in many other ways too – for instance, in the automotive and telecommunication sectors. Imagine the roof of a car ‘painted’ with a perovskite that produces electricity to power some of the vehicle’s equipment... or a cell phone with one side coated in perovskite film. We have already carried out such tests. Imagine that all you need is light from a lamp at home to stop the battery in your smartphone from running down – and that if you left the same smartphone out in the sun, you wouldn’t even need a traditional charger. A silicon panel cannot do this.

Now for a question that our readers have probably been wondering about since the beginning of our conversation: how much are perovskites going to cost? For example, for a phone like this coated with them.

I’m not trying to avoid this question, but... it’s difficult to answer right now. Our philosophy is to sell a large number of cells to companies for them to combine with their products, so the final price will depend on the phone manufacturer.

So how much will a square metre cost?

It is difficult to specify right now. We are building our first production line, which will also have testing facilities. We estimate an initial capacity of 40,000 sqm of perovskite film per year, although we are already planning to expand the line and double its capabilities. The plant should be completed in the middle of next year, so the first products will probably become available at the end of 2019. This is when we will be able to set prices. We are constantly refining the the product – trying to identify the best shapes and colours. But the technology itself is already there. It’s clear that it works and will soon revolutionise the world. And we will play a role in this revolution – that’s a unique feeling. ν Skanska is the content partner for the Innovations by Skanska section of the magazine

The woman who prints electricity

Olga is a Polish physicist and the inventor of the revolutionary method of producing solar cells based on perovskites.She graduated in physics from the University of Warsaw as well as the Catalan University of Technology in Barcelona (where she was awarded her master's degree) and the University of Valencia where she defended her PhD at the Institute of Molecular Sciences. While working in Spain she developed a method that makes it possible to use of perovskites on any base such as a plastic film. In December 2014 Saule Technologies, the company she founded, presented the world's first printed perovskite cell in Boston. She has won numerous awards and distinctions. She was the first Pole to be awarded the title of ‘Innovator of the Year’ by the Massachusetts Institute of Technology magazine. In 2016 the President of the Republic of Poland decorated Olga Malinkiewicz with the Knight's Cross of the Order of Polonia Restituta ‘for her outstanding contribution to the development of Polish science’.

Adam Targowski

the sustainable development manager of Skanska’s office division

The developer’s view

At Skanska our priority is sustainable development that serves people in the best possible way and that does not have an adverse impact on the environment. The aim of the project we are working on with Saule is to develop a system to ensure the energy self-sufficiency of office buildings with the fewest possible changes to the construction. At the same time we are striving to ensure that this technology does not havean adverse effect on the appearance of buildings. That’s why perovskites have so much potential. Over the next few weeks we will be installing a test element coated with perovskite cells onto the façade of the Spark C building in Warsaw. This will be the first industrial application of photovoltaic cells applied to the external materials on a building. As a result, we will be able to see in practice how applying cells to a façade affects the construction. We are aware that launching such a project on a mass scale requires production and construction to be optimised. Because of the progress we’ve made so far, and the fantastic assistance we’ve had from various organisations from the world of business and science as well as the fact that our tests are ahead of schedule, we feel very optimistic about the whole project.